By Nick Griffin

While aware and informed Americans weigh the possible threat of Chinese bio-terrorism, and Brits learn about their Labour government’s cover up of a Chinese spy ring, one of the biggest of the giant red Chinese elephants in the world’s living room continues to go all but unnoticed:

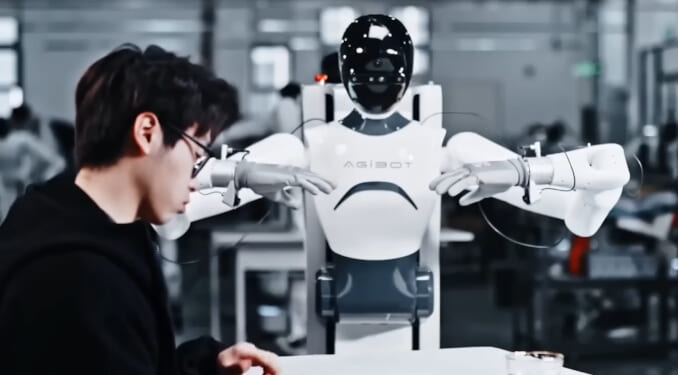

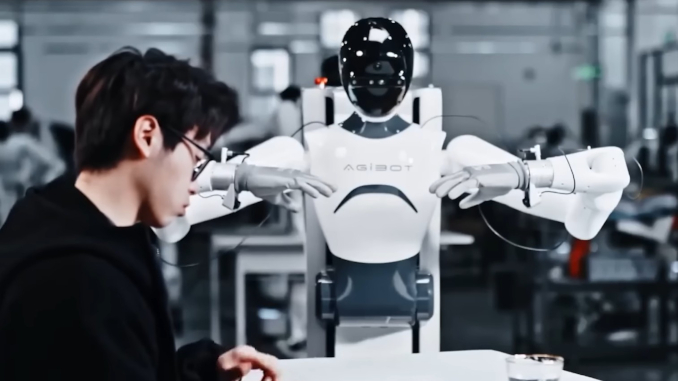

China has emerged as a global frontrunner in the robotization of manufacturing production. The once backward communist nation is significantly outpacing the United States and other Western economies in both the scale of robot deployments and the adoption of advanced automation technologies.

Click the Link Below to Listen to the Audio of this Article

This lead is driven by a combination of government policies, demographic necessities, and strategic investments, allowing China to transition from labor-intensive manufacturing to high-tech 21st-century production systems. The advances of the last decade have made China dominant in robot installations and density, as well as in emerging high-value technologies such as electric vehicles (EVs), batteries, alternative energy, and drones.

China now has a commanding lead in the robotization of manufacturing, accounting for over half of global industrial robot installations. The communist economic giant is running away with the setting up of what are called “dark factories”—fully automated facilities operating without human workers or lights—primarily in high-tech sectors like electronics and EVs.

Ford Chief Executive Jim Farley recently returned from a fact-finding trip to China, shaken by the difference between its motor industry and its stateside counterparts. “It’s the most humbling thing I’ve ever seen,” he said, after visiting various factories and seeing for himself the technological innovations being put into standard Chinese cars —from self-driving software to advanced anti-collision censors and facial recognition.

If you are still inclined to think of Chinese goods as “low quality junk,” Farley warns you to think again:

Their cost and the quality of their vehicles is far superior to what I see in the West. We are in a global competition with China, and it’s not just EVs. And if we lose this, we do not have a future at Ford.

The car industry boss isn’t the only Western executive to have been shocked by the speed and scale of the Chinese advance. Australian mining billionaire Andrew Forrest had his company, Fortescue, set to build electric vehicle power trains. His visit to China led directly to him dropping the plan altogether, writing off the fortune already spent rather than throwing good money after bad:

I can take you to factories in China now, where you’ll basically be alongside a big conveyor and the machines come out of the floor and begin to assemble parts.

And you’re walking alongside this conveyor and after about 800, 900 meters, a truck drives out. There are no people—everything is robotic.

Such factories don’t even need lights, because the robots can do the work in the dark.

Greg Jackson, the boss of UK energy supplier Octopus, describes how:

We visited a dark factory producing some astronomical number of mobile phones. The process was so heavily automated that there were no workers on the manufacturing side, just a small number who were there to ensure the plant was working.

You get this sense of a change, where China’s competitiveness has gone from being about government subsidies and low wages to a tremendous number of highly skilled, educated engineers who are innovating like mad.

New figures from the International Federation of Robotics show how much the communist regime has transformed the country’s industrial base over the last decade. Between 2014 and 2024, the number of industrial robots in China leapt from 189,000 to more than 2 million.

Last year alone, China added 295,000 industrial robots to its total. This compares to 34,000 in the USA, 27,000 in Germany and a pitiful 2,500 in the United Kingdom.

The difference is not just down to the size of China’s population and economy. China also has a massive lead when it comes to robot density. It now boasts 567 robots for every 10,000 manufacturing workers, compared to 449 in Germany, 307 in the United States and just 104 in Britain.

Particularly shocking for Americans, however, should be the fact that, despite Donald Trump’s talk of an economic miracle, it is not only China that is ahead of America in robot density. The U.S. figure of 307 per 10,000 workers is dwarfed by South Korea’s 1,012 and Singapore’s 770 robots for every 10,000 manufacturing workers.

Part of the reason for the Asian nations’ intense push towards robotization is an attempt to deal with their rapidly aging populations. But, as explained in past columns here in American Free Press, the United States is in exactly the same downward demographic spiral. The difference is that the East Asians are making a really serious effort to do something about it, while Trump is still talking about how tariffs will bring jobs back to American shores. That’s all well and good but, for American industrial might, it’s starting to look like planning to refight the last war.

On the subject of war, China now produces 70%–80% of commercial drones. It holds 79% of global patents and leads military drone sales. This is one of the results of their “Made in China 2025” program, which was launched in 2015. It is a blueprint for industrial transformation, aiming for 70% self-sufficiency in high-tech by the end of this year and global dominance by 2049.

It prioritizes robotics, AI, electric vehicles, batteries, renewables, and drones through subsidies of hundreds of billions, low-interest loans, tax breaks and a massive concentration on engineering and related advanced subjects in higher education. The plan demanded technology transfers from foreign firms and encouraged acquisitions, starting with a buying spree of $45 billion in the United States in 2016 alone. That’s an awful lot of know-how and industrial secrets.

Where does this leave America? Falling behind, and losing the war for industrial survival, let alone dominance. When Trump has finished trying to remake the Middle East, he needs to put some serious effort into remaking American industry.